Main Features

- High Performance Pressure Guide

- Single Touch Switching of Electrode Stroke

- Easy to Read Pressure Gauge

- Bottom Exhaust for a Cleaner Working Environment

- Clean High Visibility Transparent Hoses

- State of Art Microcomputer Timer

- Equipped with Weld Interlock

- Equipped with Weld Over Output Signal Function

- Perfect Weld Nugget of the Kind

- Low Energy Consumed by Inverter PWM Method

- Maximize Electrode Lifetime by Shorten Welding time

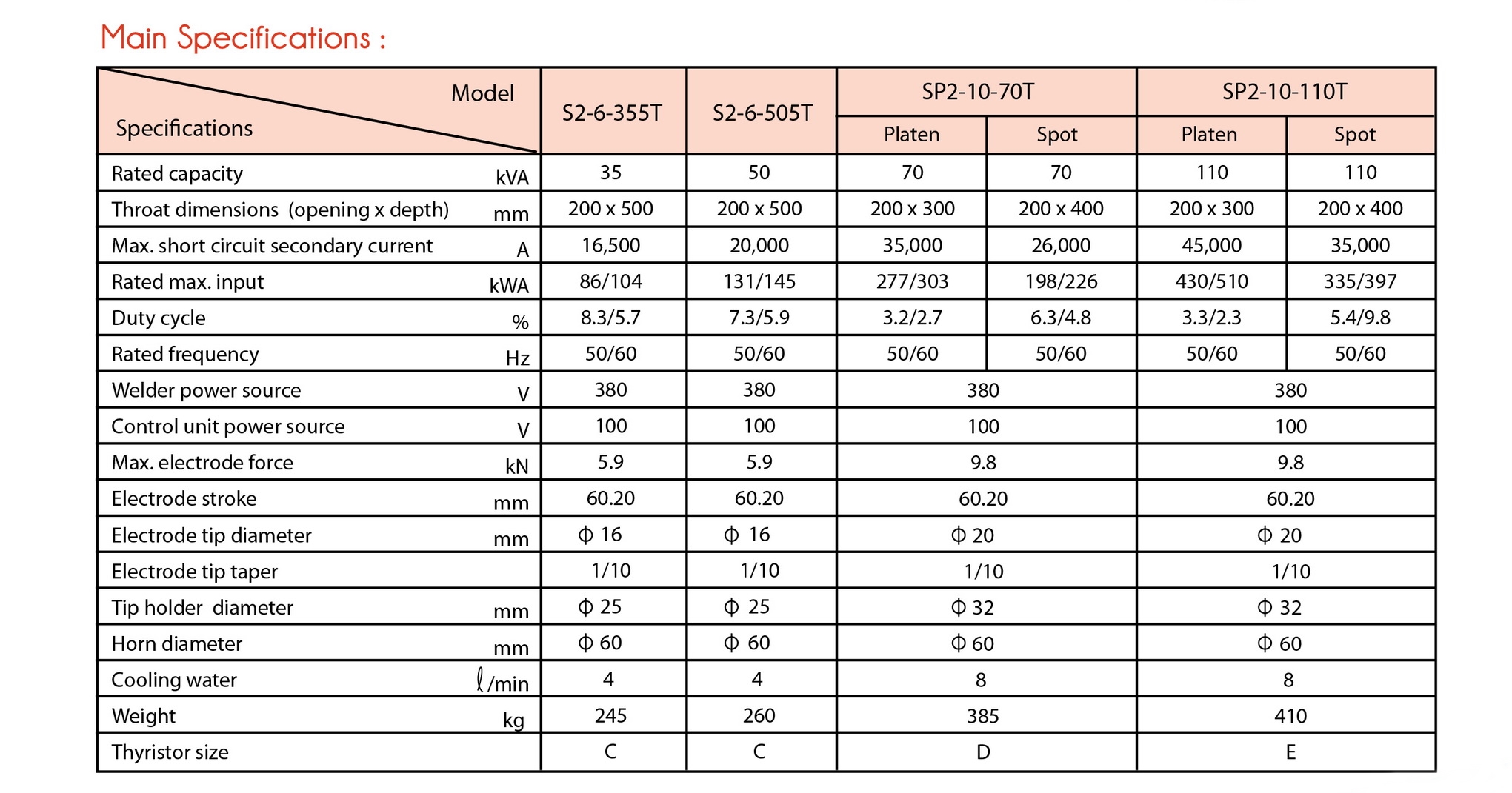

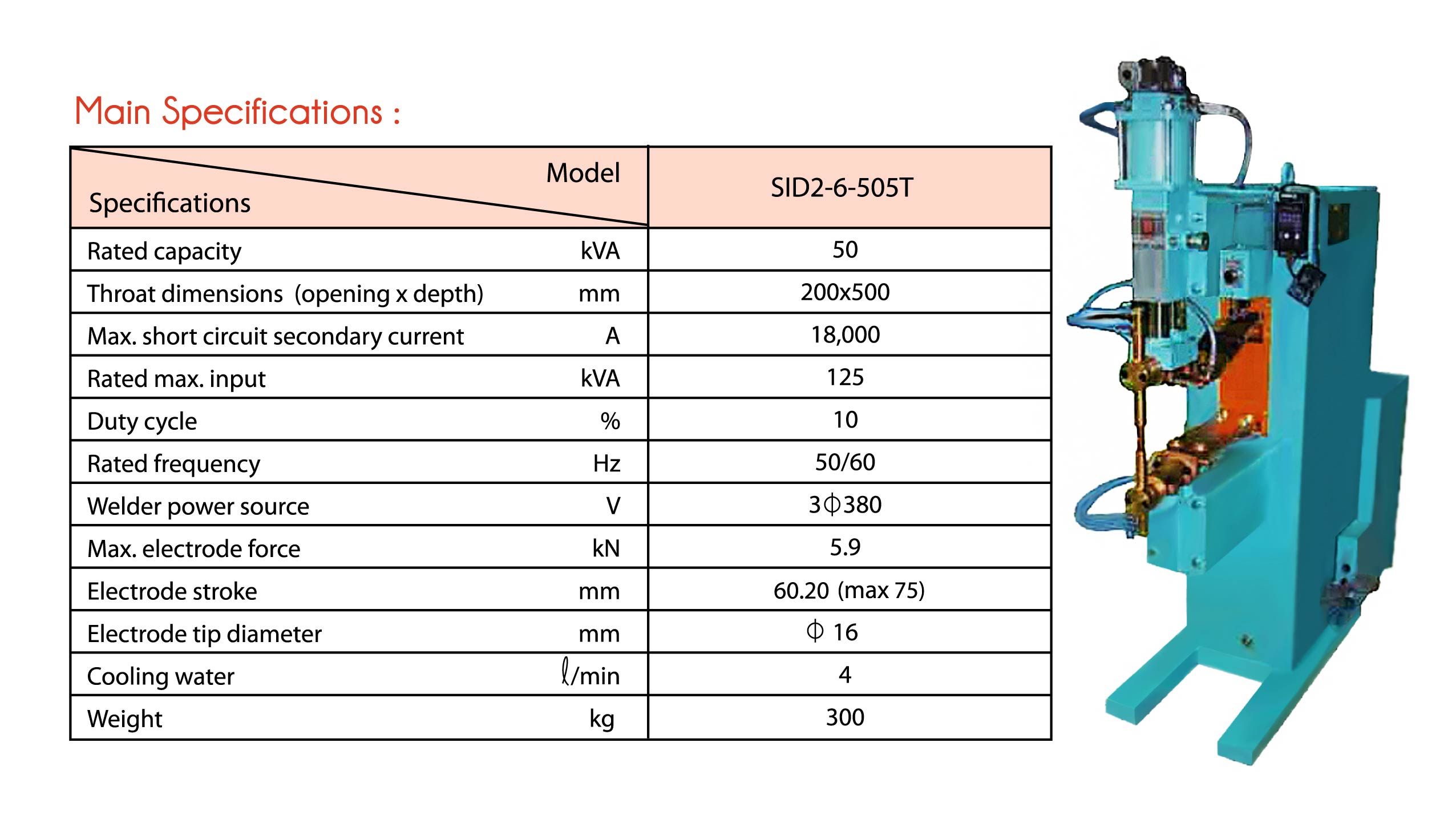

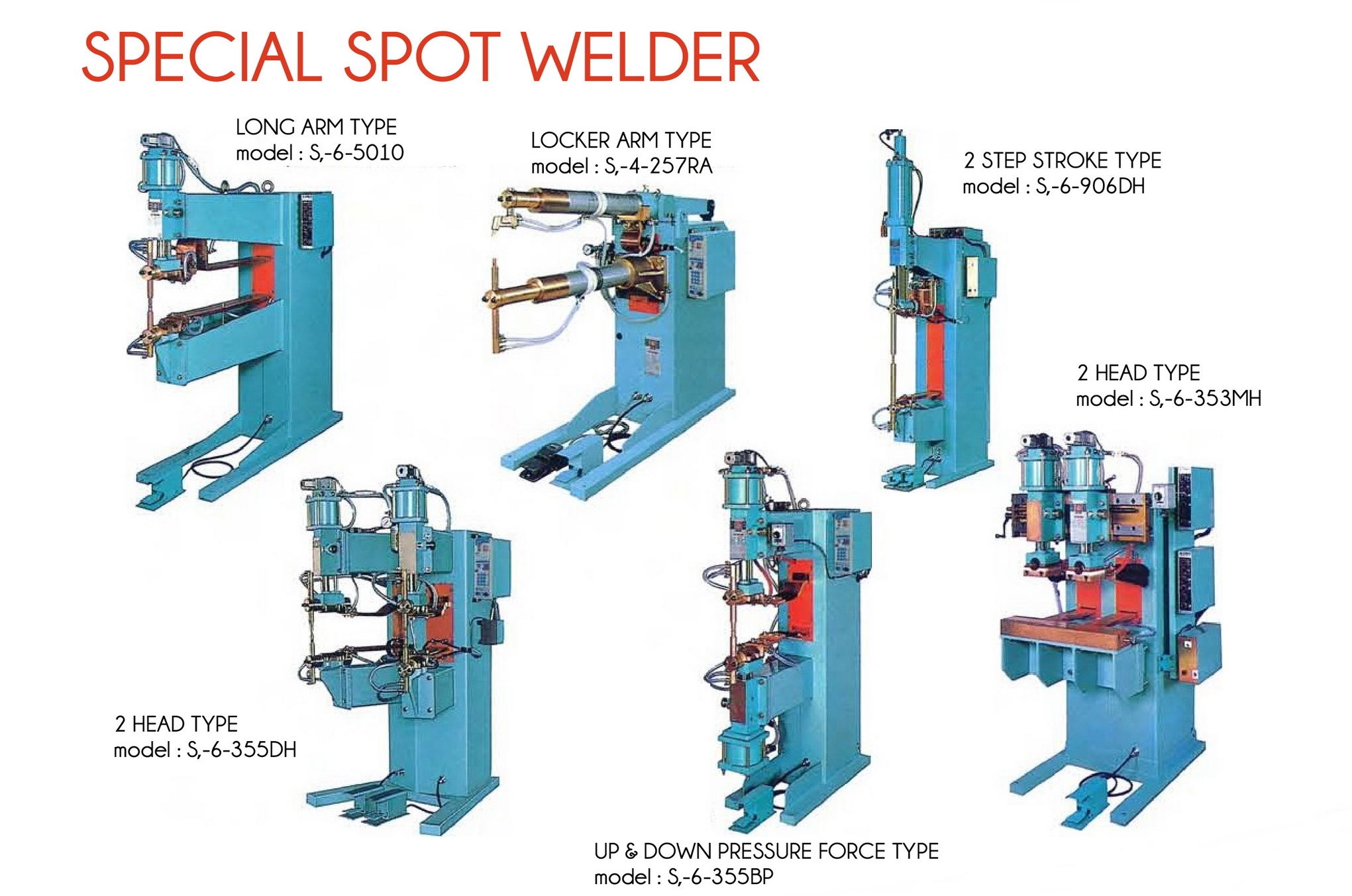

S TYPE SPOT WELDER and SP TYPE SPOT & PROJECTION WELDER

Non-oil supply guide is adopted considering the environment and there're 9 types of wide variation available.

FEATURE FOR S2 Series:

1. Non-oil supply inflating guide with high performance adopted. (Electrode stroke is of one-touch switching)

2. A ball valve mounted at feed - water inlet.

3. Transparent hole available for stream confirmation.

4. Microcomputer timer mounted (welding time interlock equipment)

5. Operation available with little cooling water (Computer with our previus type / under 50kVA)

FEATURE FOR SP2 Series:

1. Spot and projection welding compatible type mounted with frame of high precision.

2. Non-oil supply inflating guide with high performance adopted. (Electrode stroke is of one-touch switching)

3. A ball valve mounted at feed - water inlet.

4 Transparent hole available for stream confirmation.

5. Microcomputer timer mounted (welding time interlock equipment)

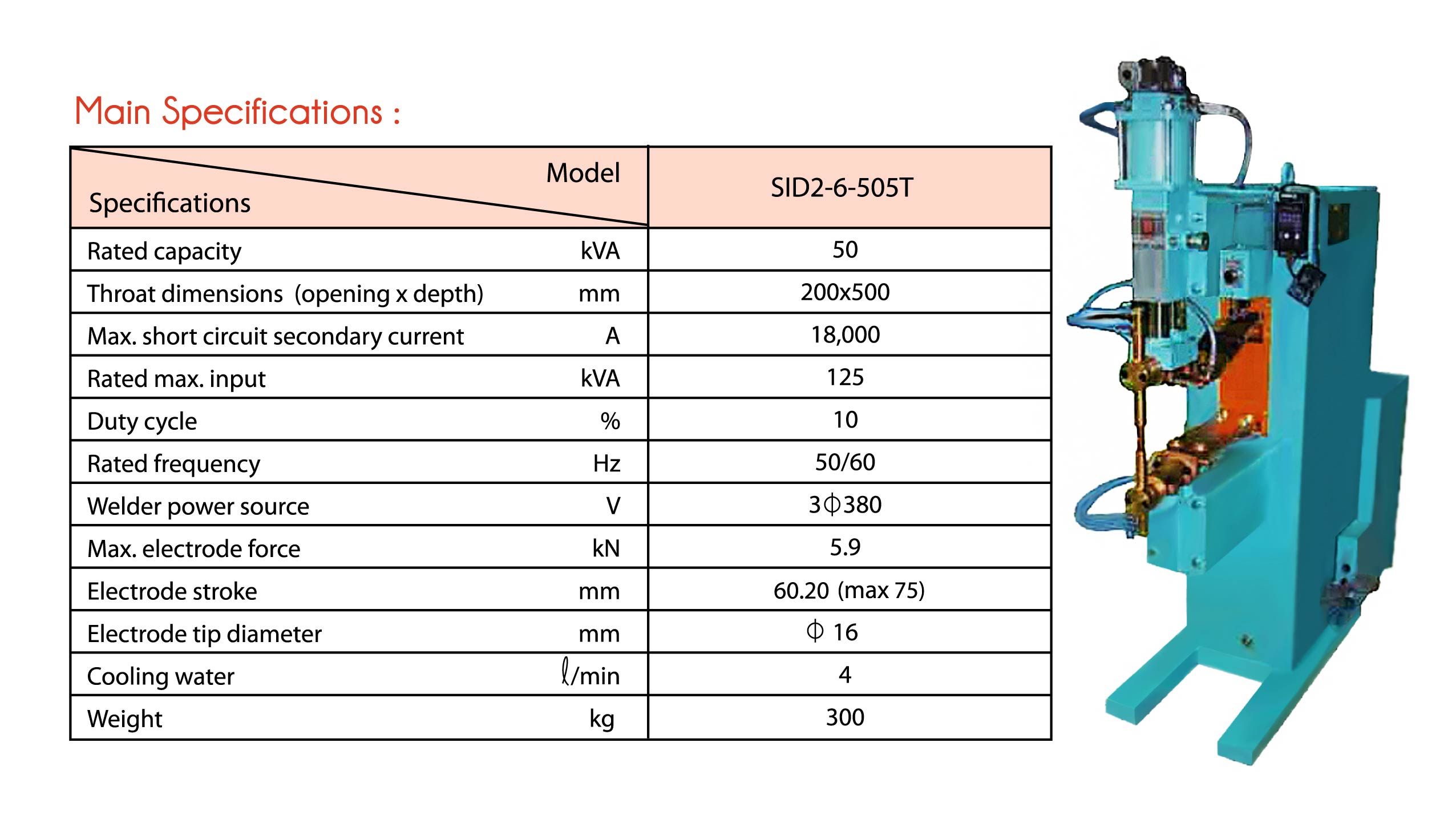

INVERTER TYPE DC SPOT WELDER

Offering high quality and wide range for welding condition, Achieve to improve a working environment and Reduce Flash & Spatter!

MAIN FEATURE:

1. Non-oil supply inflating guide with high performance adopted. (Electrode stroke is of one-touch switching)

2. Output with DC high-frequency current of good heat efficiency.

3. Input unbalance improved by 3-phase balanded loading.

4. Short time welding available, electrode abrasion reduced.

5. Space saving with inverter power buit in the frame.

6. Inflating auto switching with electro-pneamatic proportional valve mounted (optional).

PROJECTION WELDER

High precision projection welder with further improved advanced feature inflating precision.

MAIN FEATURE:

1. Dymamic precision improved with a high efficiency design.

1. Dymamic precision improved with a high efficiency design.

2. Precision needle bearing adopted at the inflating guide.

3. Stable quality compensated, such as muktipoint, ring projection.

4. Simple setup change of the jig electrode.

5. Support big work or special shaped work.

6. Power sving type.

6. Power sving type.

7. Electric transformer with perfect durability.

8. Microcomputer timer mounted (welding time interlock equipment)

9. Semi-permanent main circuit switch adopted.

9. Semi-permanent main circuit switch adopted.

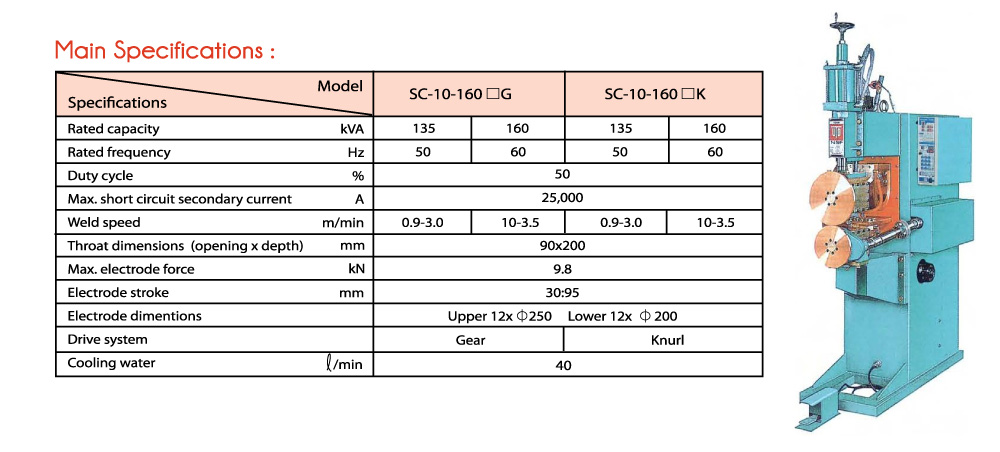

SEAM WELDER

Latest technologu added to the function pursued by different using condition and newly developed power supply housing adopted!

MAIN FEATURE:

1. High performance pressure quide and cylinder.

1. High performance pressure quide and cylinder.

2. Uses silver contacts point in conductivity part.

3. 3-phase induction motor for electrode housing drive.

4. Free select drive system.

5. Equipped welding tranformer to with stand highly severe work conditions.

6. Slim and Compact type part.

7. Easy maintenance for electric supplied housing.

8. State of-the-artmicrocomputer.

![]()