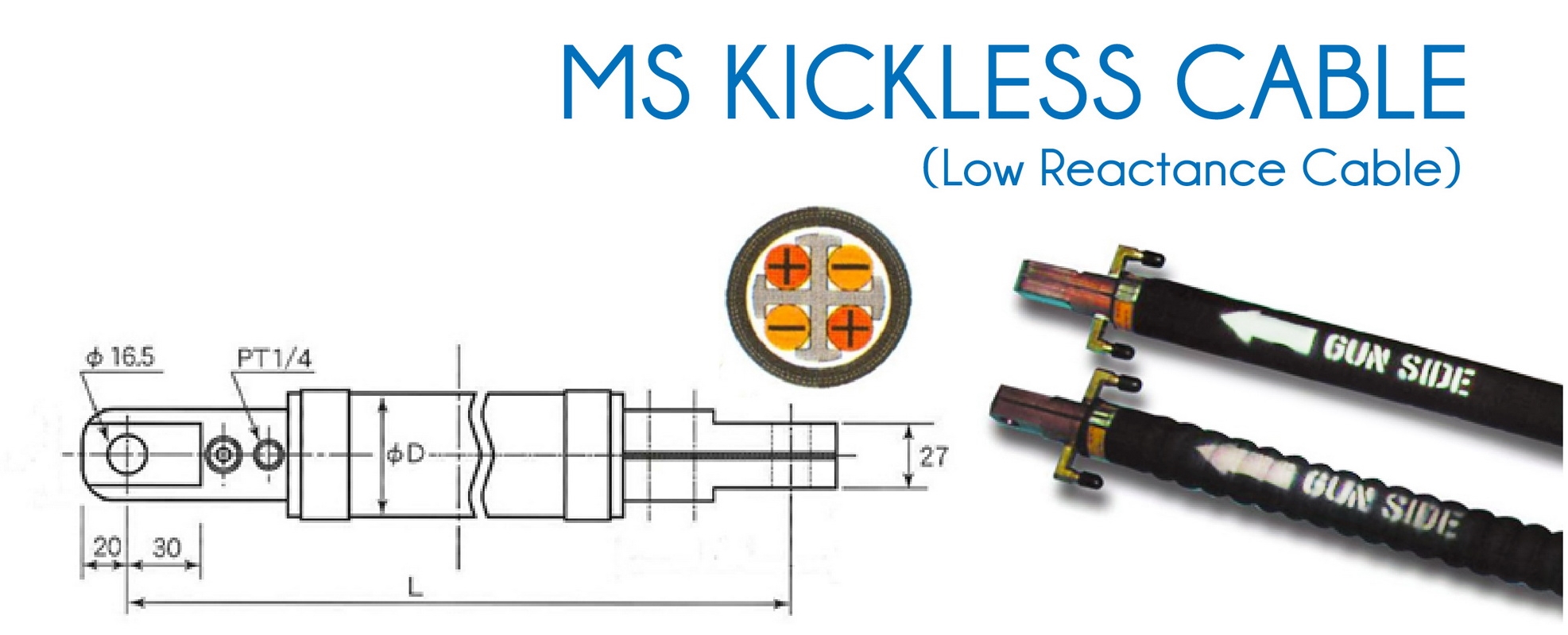

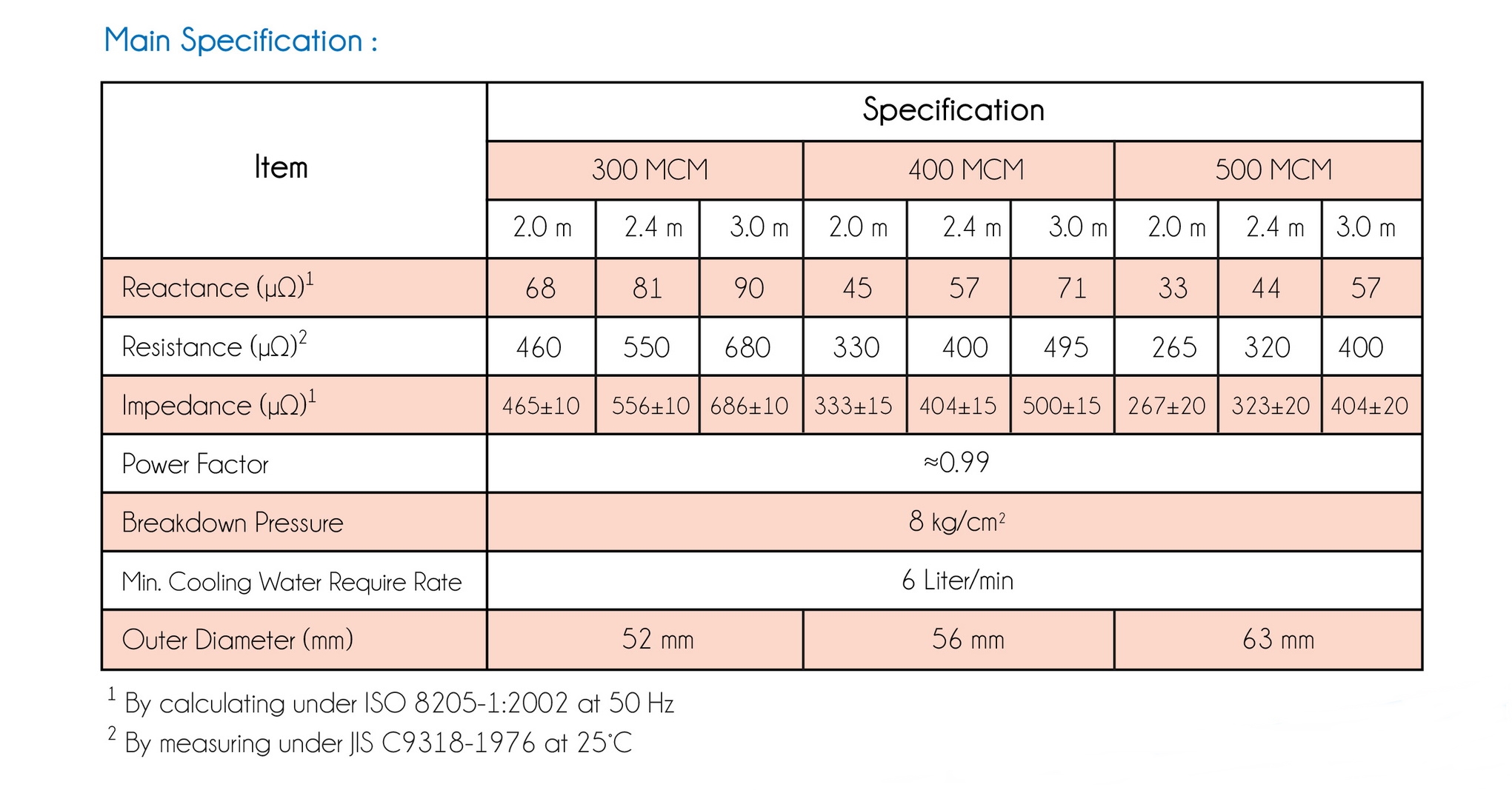

MS's advanced design in alternate polarity welding cables combines the low reactance feature of an alternate polarity cross-section with a truly unique connection at the terminal end. The result is a high performance, long lasting, welding cable suitable for the high standards of the automotive and resistance welding industries. The positive and negative ropes are positioned alternately throughout the cable and also at the connection point. This produces the lowest possible inductive reactance. Each individual strand of the cable has it own swaged on copper mini-lug. The mini-lugs are then bolted and soldered to the inside end of the terminal. Each terminal half is stamped and machined from high conductivity copper forging with a cross-section exceeding the MCM rating of the cable. The arrangement provides excellent conductivity.

Main Features

- Unique “X-shape” separator maintains strand positioning and equally distributed cooling water flow

- State-of-the-art 4-wire design to minimize current loss, reduced CO2 emission

- Electrolytic tough pitch annealed, bare copper wire, 28 AWG, herringbone rope construction for greater flexibility and reduced wear point

- High temperature internal restraining collars to minimize stress in the bending area

- Lowest reactance of the class to engage lower primary power demand

- No noticeable pulsation due to low magnetic kicking

- Improved flexibility, smaller bend radii comparing to previous model

- Reduced operator fatigue, higher productivity

-

All customized length is available upon request